Author: Boat Accessories Australia Date Posted: 24 November 2015

Spark plugs are a crucial part of your boat engine as they’re responsible for making the combustion happen that powers it.

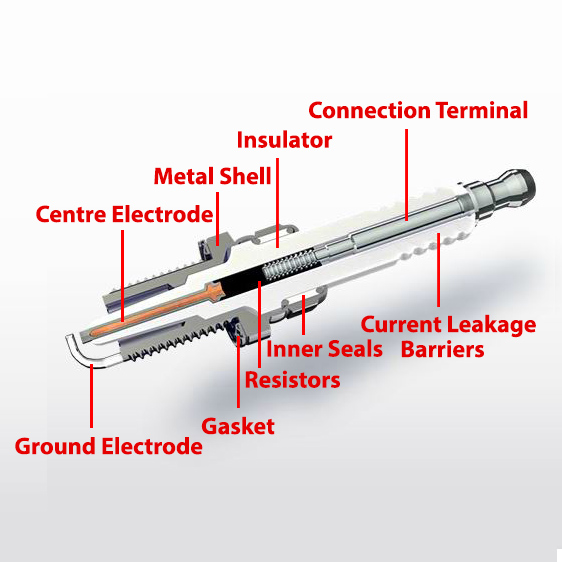

And despite their relatively simple operation, there are many important parts that make up a standard spark plug. Here is a basic overview of the most essential parts involved -

|

|

Connection Terminal

The connection terminal is usually an SAE ‘barrel’ shaped connection or a 4mm thread. The high tension ignition lead or direct ignition coil is plugged onto the terminal. This connection allows the high voltage to be transferred to the firing end of the spark plug.

Some NGK spark plugs will feature a removable terminal nut or both Terminal nut and threaded stud connection types. In this case the plug is manufactured with a threaded terminal stud, then a screw-on terminal nut is added to the plug or package to allow it to be used with either connection type.

Insulator

The ceramic insulator provides a high degree of electrical insulation to prevent high voltages from discharging to earth externally via the engine casting or other components. It also allows efficient transfer of the heat of combustion from the firing end to the cylinder head.

Current Leakage Barriers

Barriers on the outside of the insulator prevent leakage of electrical energy to the vehicle body earth by increasing the length of the path the current would have to travel to reach the earth point provided by the metal shell.

This in effect is like having a significantly taller insulator section ensuring that electrical energy takes the path of least resistance – through the centre electrode.

Gasket

The gasket ring prevents any possibility of combustion gas leaking past the spark plug due to the extremely high combustion pressures. In doing this it prevents any cylinder pressure losses. Another important function is that it provides superior conduction of heat to the cylinder head and evens out the different expansion properties of the cylinder head and spark plug housing.

Other variations include tapered seat plugs that come without gaskets that should be tightened one sixteenth of a turn past hand tightening. Regardless of the plug, never over tighten.

Inner Seals

The inner seals create a gas-tight connection between insulator and metal housing. The seal is made from a talcum ring enclosed between two additional stainless steel sealing rings. During production of the spark plug the talc ring is compacted tightly ensuring a perfect gas tight seal.

Metal Shell

The metal shell plays an important role in the thermal conductivity as it is part of the mechanism of transferring heat away from the insulator to the cylinder head. The thread on NGK plugs are formed by rolling as opposed to being cut that has the advantage of leaving no sharp edges that could damage the threaded bore in the cylinder head.

Centre Electrode

The centre electrode of a standard spark plug is comprised mostly of a nickel alloy. From the end of this electrode the spark must jump over to the ground electrode. NGK’s spark plugs have a copper core, which significantly improves the thermal conductivity preventing overheating.

Resistor

In order to ensure electromagnetic compatibility and thus fault-free operation of onboard electronics, a ceramic resistor is used inside the spark plug as an interference suppression device. This is constructed by fusing carbon and glass compounds to form a solid component within the plug that also prevents interference with electronic components not located on the vehicle e.g. domestic televisions and radios.

Ground Electrode

The ground electrode of a standard NGK spark plug is made of a special nickel alloy. It provides the opposite electrical pole to the centre electrode.

Replacement Spark Plugs

To correctly identify the spark plug part number you need, visit the NGK website and at the top right hand corner click “PART FINDER” and follow the steps.

https://www.ngk.com.au/products/spark-plugs/

Once you know the NGK part number you can search this number on our website or call us to confirm if it is a part we stock. Alternatively view all our spark plugs here.

For more information on the different types of NGK Spark Plugs, head to the NGK brand page or check out the video below.

Part number help

By: Sophie on 27 January 2022Hi, how do I know which spark plug I need?

Thanks, Sophie

Boat Accessories Australia Response

Hi Sophie,

Thank you for your comment. Please pop back online and re-read the end of this blog as I have now updated it to include more information on how to find the correct replacement spark plug for your engine.

If you have any further questions, please do not hesitate to contact us.

Thanks, Alison